Optimize timing and enhance precision in the most critical phase: prototyping. Calculate production times for uppers, manage materials more efficiently, and make quick, informed, and strategic decisions—even without physical prototypes or samples.

Digitalizing Footwear Prototyping Together

- Specialist consulting and customized process analysis

- Tailored software implementation to forecast and optimize production

- Integration with your existing management systems

- Technical support and post-implementation monitoring

- Automatic updates and simplified upgrades

- Practical training and continuous support for your team

Prototyping is a critical step in footwear manufacturing, directly affecting timing, costs, and quality, and ultimately influencing your competitiveness in the market. Relying on targeted digital solutions allows you to surpass the limitations of Excel spreadsheets, instantly providing accurate and realistic estimates of upper manufacturing times, using a replicable, updatable, and shareable approach.

Innovio supports you throughout this journey—from initial consultation to personalized software implementation, operational support, and team training. This enables you to balance workloads among different resources immediately, eliminating potential errors and delays, and achieving a faster, leaner, and more sustainable decision-making process.

Forecast and Optimize Footwear Production Times—from Stitching to Delivery Planning

Pre-calculate Production Times and Materials

Get extremely accurate estimates right from prototyping. Forecast costs, optimize resources, and eliminate inefficiencies before actual production begins, using software specifically designed for footwear manufacturing.

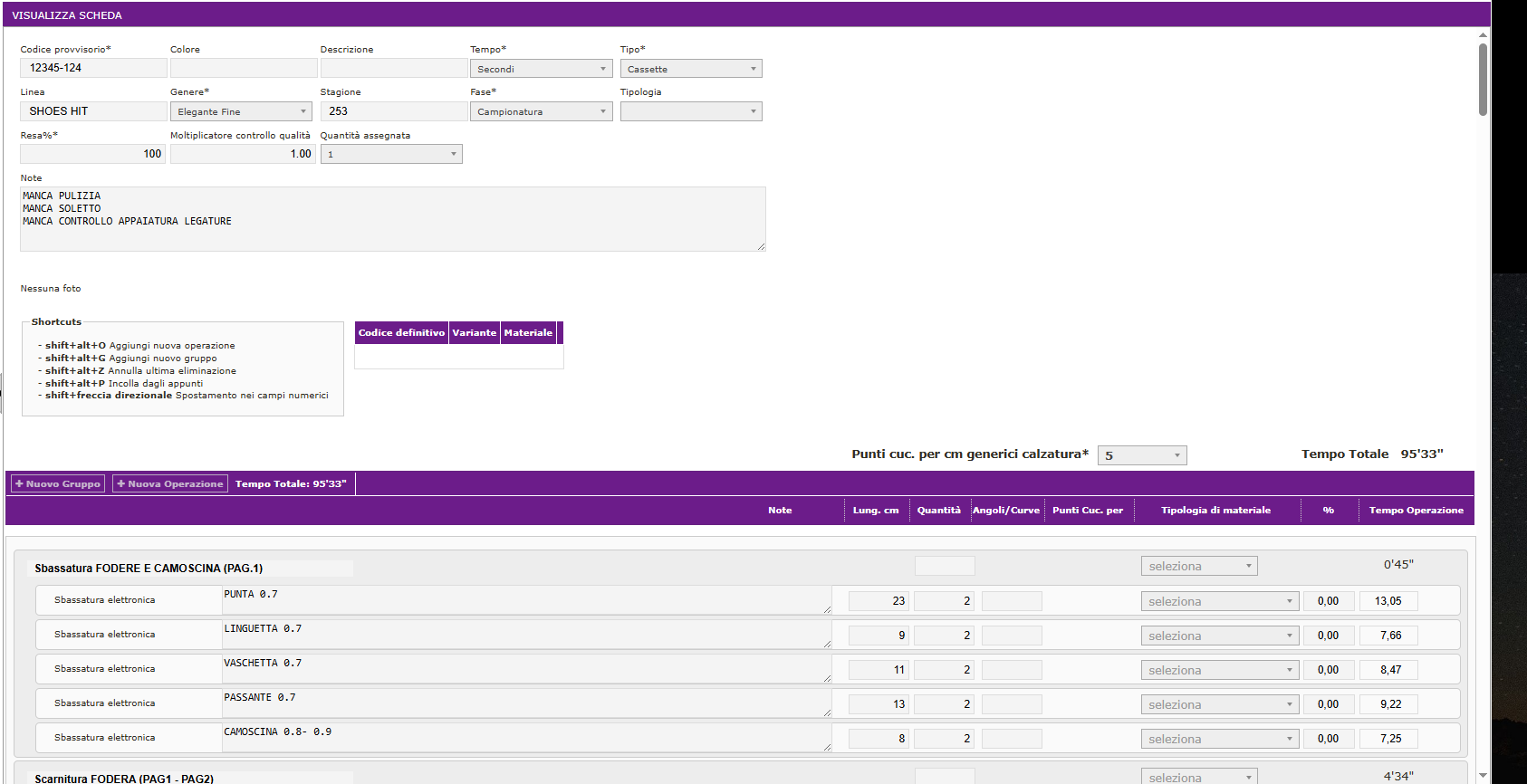

Create Reliable Time Sheets Without Prototypes

Precisely analyze stitching operations for each model, defining SKU, season, gender, yield, and description. The system generates reliable upper-time estimates, perfect for prototyping, sampling, and production.

Configure and Customize Every Operational Detail

Access over 540 ready-to-use operations and 80 pre-defined activity groups. Add, modify, or duplicate each operation, specifying time sequences, stitching points, angles, curves, and complex materials.

Manage Shoe Types, Quality Levels, and Complexity

Adjust parameters according to shoe type—sports, elegant, or classic—and desired quality level. Account for specific difficulties related to materials to achieve results consistent with the final product.

Dynamically and Realistically Calculate Times

Set coefficients, learning curves, special factors, and production constraints to ensure an always updated and optimizable time sheet, even during ongoing work.

Integrally Balance Resources and Equipment

Plan machinery and operator allocation based on priorities, volumes, and deadlines. Reduce bottlenecks and potential delays with a clear overview of stitching and assembly stages, ensuring more efficient production.

Access Real-Time Cost Reports and Analytics

Monitor costs, quantities, and timings with instant updates. Visualize the impact of each design decision in real-time. Track key indicators for immediate interventions and improved profitability.

Easily Import and Export Your Data

Connect the software with your Excel tools to create sheets from existing SKUs. Save, archive, print, or email data as PDFs for seamless, traceable sharing.

Plan with Greater Confidence

Generate comprehensive reports summarizing timings, costs, and the impact of each design choice. Evaluate final profitability, reduce surprises, and strategically prepare for production, keeping every variable under control.

Work Anywhere, On-Premise or in the Cloud

Choose between local or remote server installation, with multi-device access for maximum flexibility. Collaborate in real-time with your team, managing prototyping and planning remotely.

Advanced Solutions to Forecast Footwear Production Times

Want to know more?

Get in touch with our professionals.

Our customer support team is ready to provide all the answers you need.

"*" indicates required fields